The recycling of plastic waste is a key factor in resource-efficient production. Particular importance is given to processes capable of sorting black plastics by type.

TRANSFER

BlackValue

Sorting of black plastics for recycling

The recycling of plastic waste is a key factor for resource-friendly production. Techniques that are capable of sorting black plastics according to type play an important role here.

Black plastics cannot be recycled satisfactorily with the technology that is available today. The soot that is used to blacken plastics absorbs most of the electromagnetic radiation in the visible as well as in the infrared wavelength range. As a result, black plastics can hardly be distinguished and separated according to type with conventional sensor technology. This not only reduces the quality of products made from recycled material but also lowers the per ton value of the recyclate. The separation of black plastics according to type therefore opens up new earnings potential for companies.

We want to overcome this technical problem by using terahertz technology. The absorption behavior in the terahertz range allows the separation of recyclate and, in particular, black plastics according to type. To date, the high expenditure associated with the development of a full spectroscopic, imaging terahertz sensor system has hindered its application in the industrial sector.

Fraunhofer FHR and Fraunhofer IOSB decided to tackle these challenges jointly. The combination of a terahertz camera with optical sensors allows complete material characterization using selected frequency bands in the low terahertz range and the acquired data can subsequently be evaluated using new analysis algorithms. Our vision is a cost-effective, realtime-capable multisensor suite with a sorting accuracy of over 90%.

BlackValue’s goals are:

- to develop a system with integrated sensors and algorithms

- upgradeability

- high separating preciseness

- applicability on plastic flakes (in particular black flakes)

- capacities of up to 5 tons per second

- cost-effective, economic implementation

The separation into pure grades achievable with this technology, combined with economic efficiency, allows the recycling of black plastics on an industrial scale. The participating Fraunhofer institutes and their industrial customers are therefore opening up new market segments.

The technological approach of the system is currently undergoing validation and in-depth testing. We assume that suitable frequencies and procedures can be found and implemented in the medium term to achieve our ambitious goals.

With you as a pioneer, decision-maker or user of the recycling industry or associated companies, we would be delighted if you could imagine a joint research and development project with us for BlackValue.

About BlackValue

Motivation and Consortium

Project Goals

Motivation and Consortium

When recycling plastics, a distinction is essentially made between mechanical recycling, feedstock recycling and thermal recycling. At present, approximately 50 % of plastic waste is recycled in Europe. The recycling method most frequently used is thermal recycling, where the waste is incinerated to generate energy. The recyclate produced during the material recycling process is used to produce new products. Here, the recycling process is complicated by the large number of plastics and the different types of additives such as colorants, plasticizers, flame retardants or UV blockers. Products that are produced from mixed recyclate have poorer material properties than products made from new plastics. Sorting systems that are capable of identifying materials and are used in plastics recycling must therefore also be capable of correctly classifying material types, regardless of the additives that are used.

Due to the specific absorption behavior of black plastics, the sensor systems currently available on the market have great difficulty meeting the challenges associated with the separation of such plastics . This class of plastics, however, will play an increasingly important role in the future as the recycling of black plastics, particularly with regard to automobile recycling, is a key factor for meeting the agreed EU limits. This gap in the recycling loop must be closed with new technologies for the separation of black plastics. To achieve this goal, a strategic alliance comprising the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB in Karlsruhe and the Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR in Wachtberg was formed.

Project Goals

The process known as recycling involves several substeps, e.g. presorting, shredding, screening, separating, utilization. The project focuses on the core technical problem associated with the separation of colored or black plastics, namely the sensors. Thanks to terahertz technology, this problem can be solved at an industrial level. The sensors are not developed in isolation but integrated in state-of-the art sorting technology together with signal evaluation. Hereby, an industry-compatible method for the sorting of black plastics is now being introduced.

This project aims to carry out research on a sorting system, above all for black plastics, which facilitates the separation of black plastics in the recycling industry. Here, the central focus lies, in particular, on the cost-effective and flexible utilization of the system. To integrate the advantages of spectroscopic investigation between 0.1 and 1 terahertz in a recycling process, it is important that a suitable reduction of the measurement data be achieved to maximize the measurement speed. This data reduction is achieved through the utilization of targeted individual frequencies or small frequency bands to separate the plastics as opposed to complete spectroscopic investigations in the complete frequency range from 0.1 to 1 terahertz. This data reduction combined with submillimeter wave technology offers a novel approach to the development of a measuring instrument which can be used flexibly in the separation of various types of black plastic in the recycling area. Furthermore, the utilization of this technology with suitable algorithms allows a retropolation of material parameters, e.g. measurement of dielectric constants, which can be used to determine the plastic type.

The evaluation of different material-specific characteristics of the samples, such as damping, the spectral fingerprint and the dielectric properties, should facilitate the identification and validation of a suitable and cost-effective approach for the separation of a wide range of optically opaque plastics (black plastics) during the course of the project. One of the main challenges associated with the construction of such a system lies in the targeted selection of the frequencies to ensure that the created data volumes and the corresponding system costs are kept as low as possible. This concept has already been applied successfully by Fraunhofer IOSB for the sorting of colmanite in Turkey. It is also important to develop a multi-stage differentiation algorithm which not only factors in the characteristic absorption of the samples but also considers the dielectric properties. As the retropolation of the dielectric properties is an important element of the sorting algorithm, it is essential that different extraction approaches be investigated under realistic conditions. Two techniques deserve a particular mention here. One technique involves determining the thickness of the sample with an additional optical sensor whereby this height information and the phase shift of the implied submillimeter wave is subsequently used to calculate the dielectric properties. Another possibility for material parameter extraction involves the utilization of the reflection geometry of a measurement configuration. Cracks that occur in the characteristic impedance, caused by the boundary layers air/sample and sample/air, are specifically determined in the raw data set to acquire the necessary parameters for retropolation

The Partners at a Glance

Two Fraunhofer institutes combine their comprehensive skills and competencies within the framework of the blackValue® project with the aim of jointly developing a reliable solution for the sorting of black plastics. Each of the institutes has decades of experience in its field of activity thus ensuring the development of a system that is in line with market requirements.

Fraunhofer IOSB

The Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB researches and develops multisensor systems to support people.

MORE INFO

Fraunhofer FHR

The Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR is one of the leading radar research institutes in Europe. It focuses on all aspects of technology ranging from system design and signal processing to the construction of hardware and software prototypes.

MORE INFOFraunhofer IOSB

Optronics, system technology, image evaluation

We research and develop multisensor systems which enhance people’s environmental awareness and interaction abilities. This starts with the generation and automatic evaluation of aerial and satellite images, e.g. of a disaster area, and extends to the sorting and quality control of bulk materials such as coffee beans or minerals.

When things get too fast, inaccessible or dangerous for humans, e.g. under water or in contaminated areas, mobile robots can be employed as sensor carriers to assess the current situation. Transparent and interactive video systems guarantee more protection and security. All of these systems are connected with state-of-the-art information technologies, for which we also develop and offer cyber security solutions.

We develop software for the planning, control and operation of industrial production processes, have web technologies for information management in complex database systems, e.g. for the collection, intelligent linking and evaluation of environmental or energy management data.

The department Visual Inspection Systems (SPR) develops and delivers systems for automatic visual inspection applications in industry. SPR is part of the business unit Visual Inspection and the core competence area Optronics. At present, the most important application areas are the automatic inspection of blister packs in the pharmaceuticals industry, the automatic sorting of bulk materials, surface inspection, color measurement of granules and print layout inspection. All applications are characterized by the fact that the inspection keeps pace with high-throughput manufacturing processes. This reflects the high processing power of the image evaluation systems that are used. High-resolution line scan cameras of various types (color and gray) are used exclusively as imaging sensors. The imaging equipment is tailor-made for the respective task and particular use is made of folded beam paths and flashed LED lighting. The products produced by the department are used in industrial applications worldwide. Marketing and service are essentially handled by partner companies. In individual cases, the business unit does, however, develop directly for the end user and also handles installation and service.

Fraunhofer FHR

The Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR develops concepts, methods and systems for electromagnetic sensors, particularly in the field of radar, together with innovative signal processing methods and state-of-the-art technology in the microwave to the lower terahertz frequency range. Its internationally acknowledged and valued competence covers almost every aspect of modern radar technology. With a budget of approx. € 29 million (2014) and approx. 285 employees, Fraunhofer FHR is one of the largest radar research institutes in Europe.

Radar and related high-frequency systems form a key technology for defense and security, particularly in the field of reconnaissance and surveillance. FHR has supported the German Ministry of Defense in this field since the foundation of the institute in 1957. In Germany, the institute has played a pioneering role in the development of new technologies for numerous applications: e.g. space reconnaissance with radar, multi-function radar systems with phased array antennas, adaptive interference suppression, millimeter wave techniques, ultra-high resolution radar imaging, moving target recognition with space-time filtering, target classification and passive radar.

In keeping with the framework conditions of the Fraunhofer-Gesellschaft, the unique role and competencies of the institute also stimulate increased involvement in civilian markets. The activities in the new business units Air and Space-Based Radar Systems, Land and Sea-Based Reconnaissance, Systems for Security and Protection, Sensors for Vehicles and Traffic, Sensors for Quality Control, Energy and Environment as well as Electromagnetic Simulation and Antenna Technology constitute concrete examples of innovative applications that are being implemented in many areas of the company.

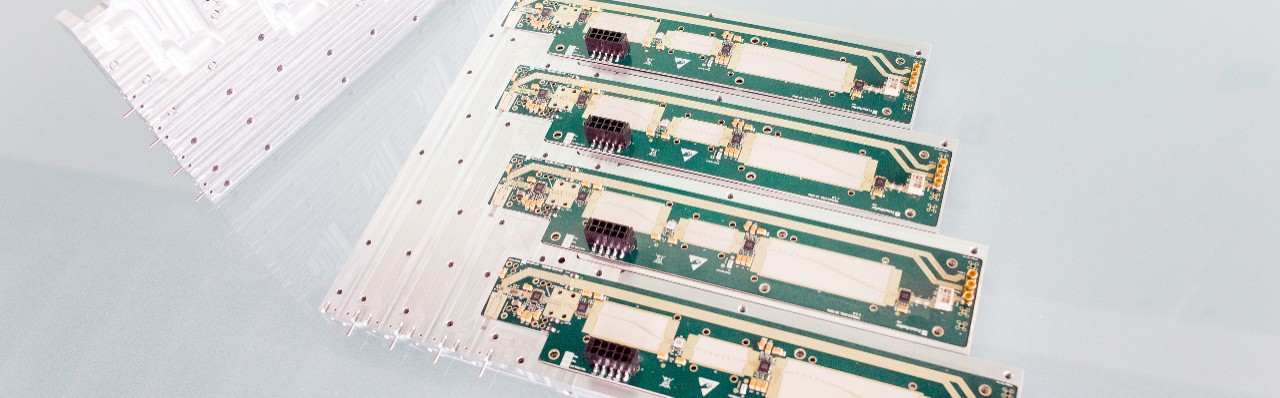

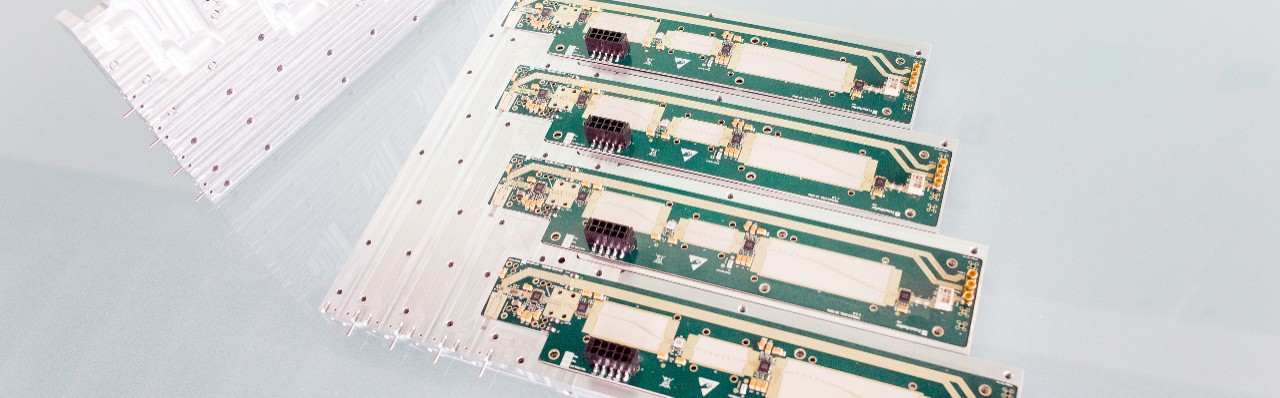

Fraunhofer FHR has worked for many years on the development of radar systems and high frequency sensors. In addition to the construction of high-performance array antennas, the institute also focuses on the development of broadband radar sensors for imaging systems. Fraunhofer FHR has developed some of the most powerful radar systems in the world, including the PAMIR system, the COBRA series and MIRANDA, the first radar system worldwide with an operating frequency of 300 GHz and a bandwidth of 40 GHz. Within the framework of expanding its civil activities, Fraunhofer FHR conducts research on techniques and processes in the field of industrial quality control. These include high frequency sensors for industrial applications, e.g. in the area of steel production, as well as imaging systems such as SAMMI, which are developed for quality assurance or security applications. In the process, Fraunhofer FHR applies its expertise in the areas of millimeterwave sensors and radar signal processing. Here, the production capacities of Fraunhofer FHR are used for the construction of cost-effective and efficient radar systems and new signal processing techniques, e.g. MIMO systems and multi-frequency, tomographic processes, are developed. The capability to produce line-scan cameras in-house coupled with the ability to adapt signal processing techniques paves the way for the realization of individual, customer-specific solutions and the flexible design of development processes.

Interesting Insights into Radar and Terahertz Technology

Photorealistic aerial images, high-precision measurement of satellite orbits, a look beneath the Earth’s surface, presentation of the air situation through the utilization of TV and radio stations – these are just a few examples of the remarkable capabilities of radar. Due to its unique capabilities – independence from weather and daylight, high distance range, high sensitivity to range rate changes and the generation of high resolution images – radar is now an indispensable tool for military and civilian applications.

What is Radar?

Radar works with electromagnetic waves, similar to radio waves. Radar can be used to generate a multitude of information and images.

MORE INFO

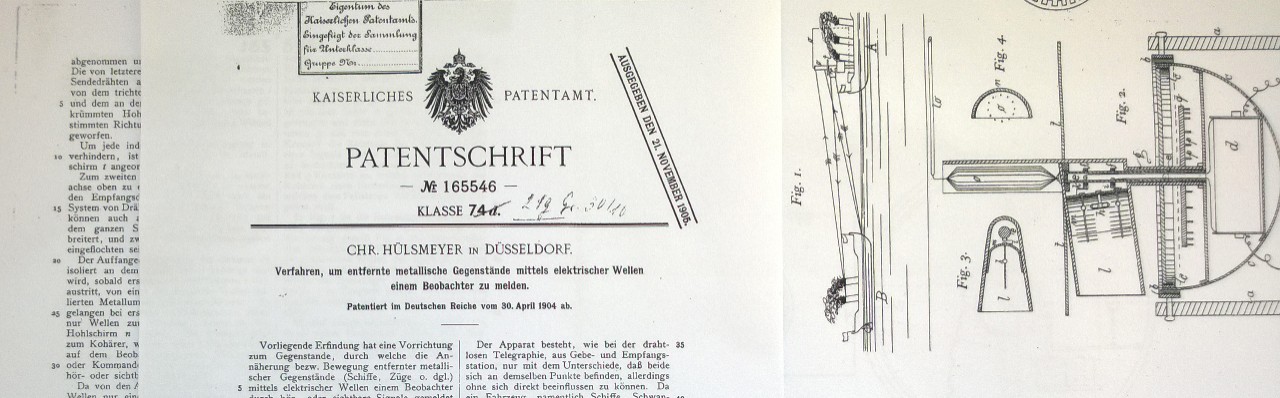

Development of Radar Techniques

Radar was inspired by Hertz’s experiments, developed by Hülsmeyer – and is now indispensable.

MORE INFO

General Information on Terahertz Technology

Terahertz refers to a frequency spectrum within radar technology – a powerful alternative to optical methods thanks to its high resolution.

MORE INFOWhat is Radar?

History of Radar

General information on terahertz technology

Terahertz waves: Broad range of applications in safety technology

The terahertz range is a part of the electromagnetic spectrum between microwaves and infrared with a frequency of one billion oscillations per second. The so-called terahertz gap was an issue for many years as there were no practical radiation sources for this part of the spectrum until well into the 1990s. Due to its special properties, terahertz radiation has become an important technology of the future: it can be used to detect concealed explosives or drugs and it can identify which substances are flowing through a plastic pipe. It is capable of monitoring the thickness of a layer in a nondestructive manner and visualizing material flaws in ceramics or plastics. Due to its low energy characteristics, terahertz radiation is non-hazardous for humans and animals. There is practically no limit to the areas in which it can be used.

Proximal and remote detection of hazardous substances

In contrast to UV radiation or X-rays, terahertz waves do not change the chemical structure of the substances that are being investigated. Hence, they are not harmful for humans and are therefore suitable for people screening. Terahertz spectroscopy can be used to specifically detect a large number of hazardous substances through numerous commonly used packaging materials or clothing. Detection is possible at distances of up to a few meters without sampling. Thanks to the short wavelengths, the spatial resolution is far superior to that which can be achieved in the microwave range. The material of a suspicious object can be analyzed by the spectrum of the radiation.Active or passive methods

Terahertz scanners function on the basis of active or passive methods. When using a passive method, scanning is restricted to the natural terahertz radiation that is emitted by the human body. The active method on the other hand uses an additional artificial radiation source via terahertz radiation. The system uses the variation of the wavelength from the backscatter to reconstruct an image.

Numerous application possibilities

Scientists have developed practical and easy-to-handle terahertz scanners and detectors. In addition to applications in safety technology, terahertz radiation can also be used in the areas of laboratory analytics, process measurement technology and quality control.

Project Sheet

Scientific Publications

Points of Contact

Dipl.-Ing. MBA Christian Krebs

Abteilungsleiter Frontend & Systeme | Bereich Industrielle Hochfrequenzsysteme (IHS)

Fraunhofer-Institut für Hochfrequenzphysik und Radartechnik FHR

Fraunhoferstraße 20

53343 Wachtberg

Phone +49 228 60882-2505

Fax +49 228 9435-192

Prof. Dr.-Ing. Thomas Längle

Head of Department Visual Inspection Systems

Fraunhofer-Institut für Optronik, Systemtechnik und Bildauswertung

Fraunhoferstr. 1

76131 Karlsruhe

Phone +49 721 6091-212